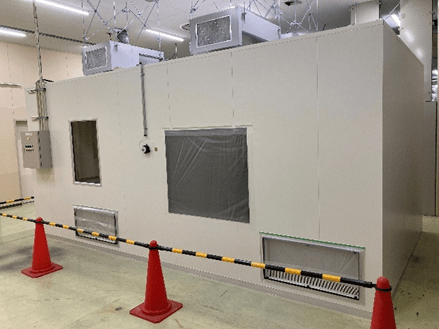

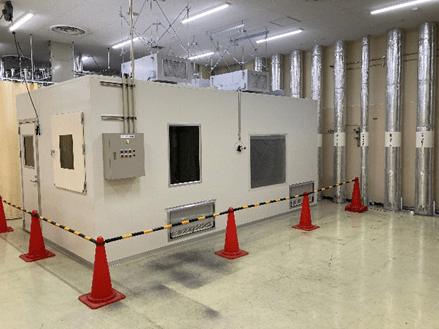

Following the establishment of Coat-X Japan in 2021 with our partner OSG Coating Services Co, Ltd, the setup of the coating service facility has taken a further step with the installation in early 2022 of the new cleanroom ISO class 6 in the Toyokawa Building near Nagoya in Aichi Prefecture. With this brand-new infrastructure, Coat-X Japan will soon be able to provide coating services in Japan and Asia under high quality and cleanliness conditions. This will be of particular interest to our customers in the medical device and electronics industries. The 15 square meter facility was designed to duplicate Coat-X’s current production line in Switzerland in combination with a specially developed Coat-X parylene and multilayer PE-CVD coating machine. This last piece of equipment will be installed in the first quarter of 2022.

The new cleanroom of Coat-X Japan in Toyokawa

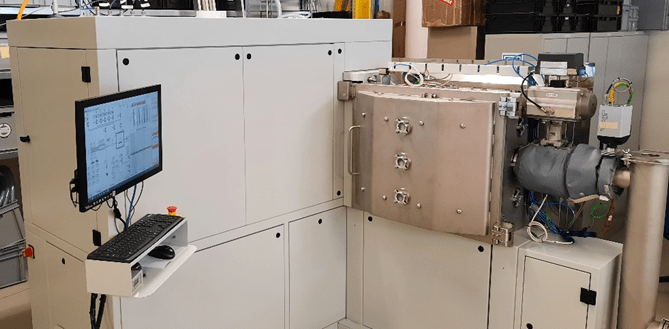

The so-called new CX3 coating machine to be installed in Japan concentrates Coat-X’s technological expertise for parylene, ceramic, and multilayer coatings in the area of thin-film encapsulation. It combines the three main processes of plasma activation, chemical vapor deposition of parylene, and plasma-enhanced chemical vapor deposition of metal oxides like SiO2 in a single reactor. This unique process integration enables high-quality, ultrapure, and highly hermetic thin films of up to 50 microns. For our medical-grade coatings, the cleanroom not only provides the required cleanliness for medical devices but will allow the final primary packaging of the coated devices as well.

Our Japanese engineering team consisting of Matsuzawa Kohsuke and Takeshi Satoshi has already been trained in Switzerland a few weeks ago, they are now back in Japan and eager to get the machine, start it, and coat parts for our Asian customers. They won’t have to wait too long as our process team in Switzerland is completing the final verification work and preparing the machine for its long journey to faraway Asia. Stay tuned for more!

The new CX3 coating machine in operation in Switzerland for qualification before shipping to Japan