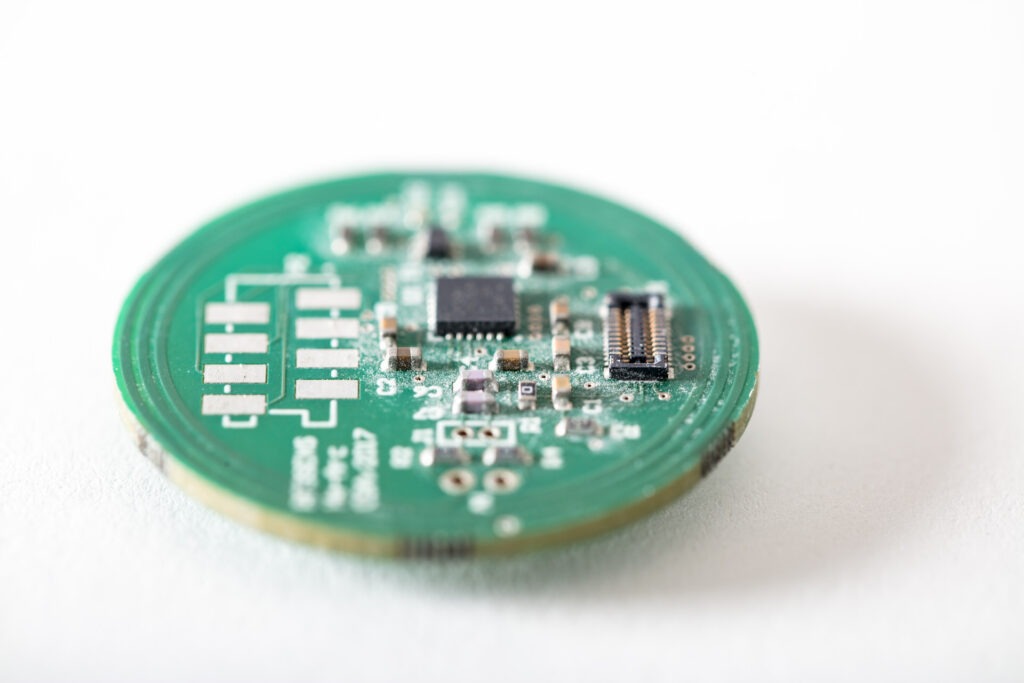

Parylene conformal coatings by COAT-X for thin film encapsulation of printed circuit board, sensors, actuators, and sensitive materials.

Offering maximal protection against moisture, aggressive fluids and gases, preventing corrosion in the long-term.

CX-PROTECT is an excellent electric insulator with a high breakdown voltage.

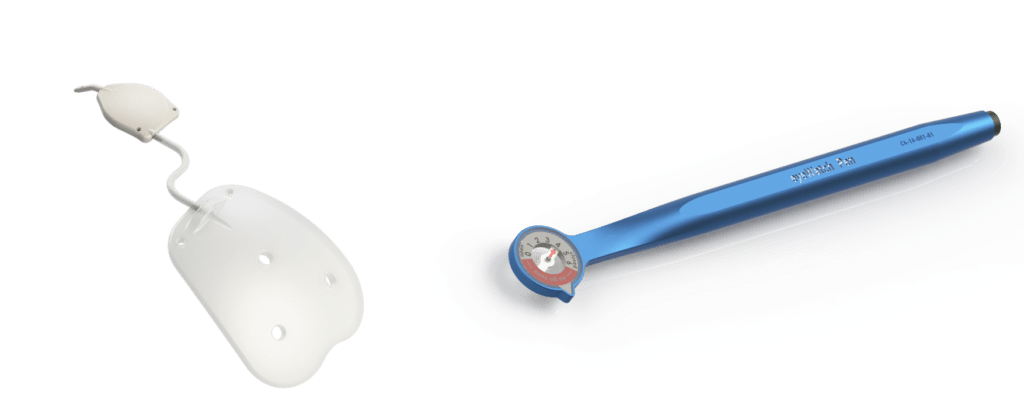

A fully biocompatible material that has been used for more than 50 years for the hermetic packaging of medical devices.

Produced with our Parylene Coaters by chemical vapor deposition (CVD) under vacuum.

Applied to metallic, non-metallic and even organic materials.

Truly conformal, perfectly covering complex shapes

Penetrating even within narrow spaces and crevices.

Thin, flexible, and very resistant to thermal cycling, not cracking, not shrinking.

Ten times more hermetic than epoxy resins allowing large volume and mass reduction.

CX-PROTECT is available in several Parylene grades

Any grade available in the thickness range of 200 nm to 30 um.

The Parylene grade must be carefully selected, depending on operating and process conditions.

The unique vapor phase CVD deposition technology of CX-PROTECT

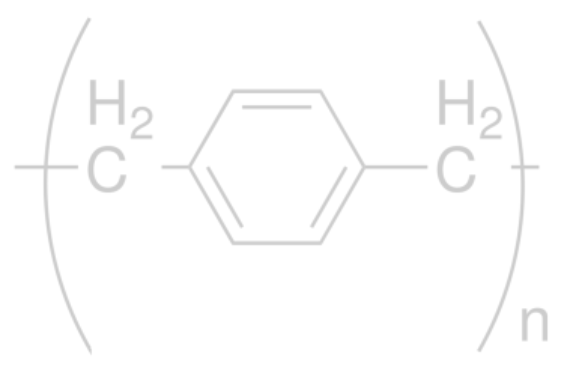

CX-PROTECT is made of Parylene, a polymer that

CX-PROTECT is an excellent electrical insulator coating with

CX-PROTECT is the ideal thin film electrical insulation for narrow, or space-limited designs.

CX-PROTECT is compatible with rigid and flexible PCB and PCBA (glass fibers, polyimides) with or without solder masks.

CX-PROTECT on PCB resists to the high temperature solder reflow process or hundreds of thermal cycles (Parylene-F grade) without delamination.

CX-PROTECT is highly transparent in the complete visible range and thus extremely useful for optical applications. The refraction index lies between 1.5 to 1.6.

For special optical or aesthetic applications like photonic or watchmaking, COAT-X has developed the ParyCLEAR grade.

CX-PROTECT is an excellent barrier against aggressive chemicals it resists most solvents, acids, and bases used in industry with no solubility in aggressive medias.

CX-PROTECT is made of Parylene a of high performance semi-crystalline thermoplastic polymers with excellent mechanical properties.

COAT-X provides coating service for CX-PROTECT protective coatings for medical devices, electronic PCB's, industrial components, jewelry pieces and watches.

Last generation plasma-enhanced chemical vapour deposition (PE-CVD) machines are available for the quick handling purchase orders.

Please fill in the fields below so we can contact you and define your needs