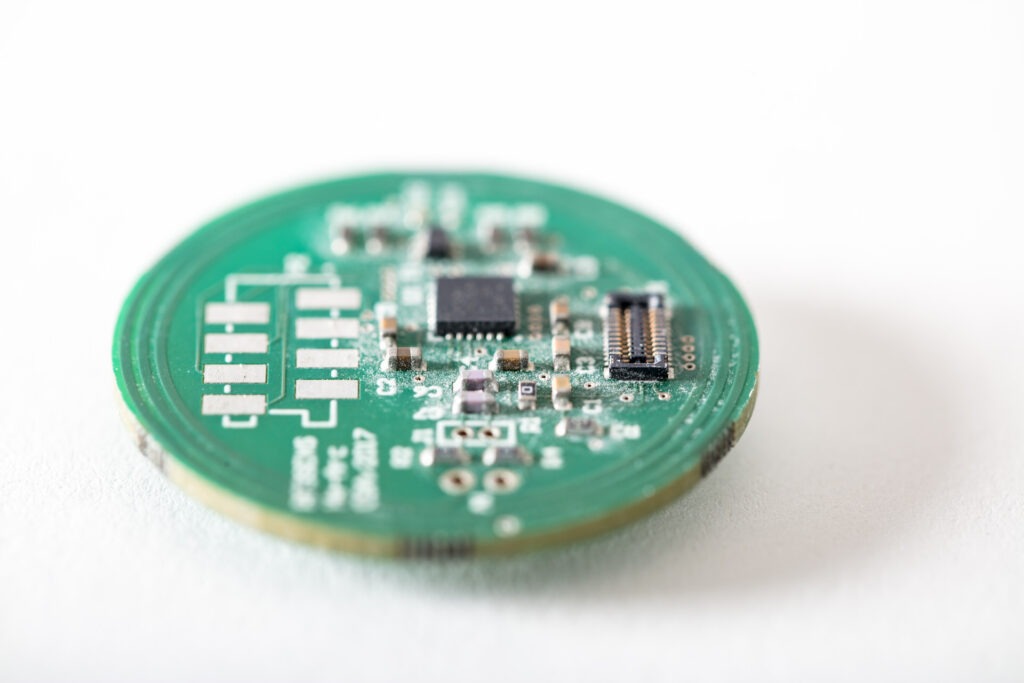

Die Parylene-Beschichtung von COAT-X für die Dünnschichtverkapselung von Elektronik, empfindlichen Komponenten und Materialien.

Bietet langfristig und unter schwierigen Bedingungen maximalen Schutz vor Sauerstoff, Feuchtigkeit und Korrosion.

Ein elektrischer Isolator mit hoher Durchbruchspannung.

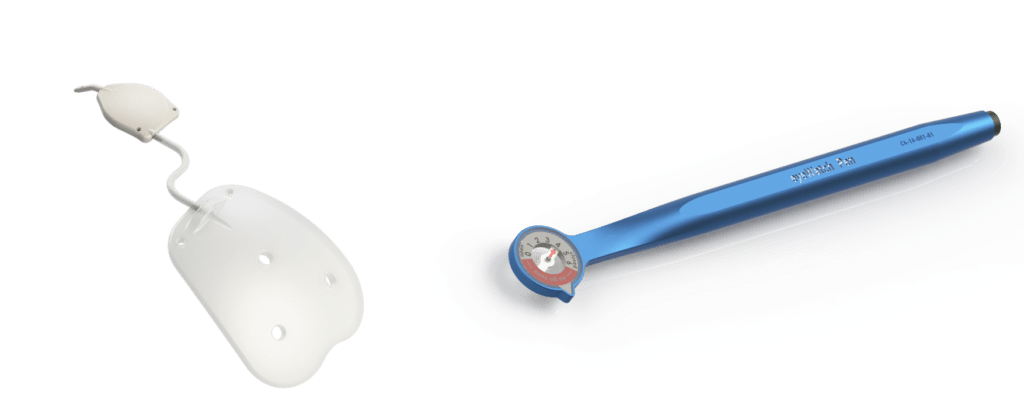

Ein vollständig biokompatibles Material, das seit mehr als 50 Jahren für die hermetische Verpackung medizinischer Geräte verwendet wird.

Hergestellt mit unseren Parylene-Beschichtern durch chemische Gasphasenabscheidung (CVD) unter Vakuum.

Wird auf metallische, nichtmetallische und sogar organische Materialien angewendet.

Wirklich konform, deckt komplexe Formen perfekt ab

Dringt auch in enge Räume und Spalten ein.

Dünn, flexibel und sehr beständig gegen Temperaturwechsel, keine Risse, kein Schrumpfen.

Zehnmal hermetischer als Epoxidharze, was eine große Volumen- und Massenreduzierung ermöglicht.

CX-PROTECT ist in mehreren Parylene-Qualitäten erhältlich

Jede Sorte ist im Dickenbereich von 200 nm bis 30 µm erhältlich .

Der Parylene-Typ muss je nach Betriebs- und Prozessbedingungen sorgfältig ausgewählt werden.

Die einzigartige Dampfphasen-CVD-Abscheidungstechnologie von CX-PROTECT

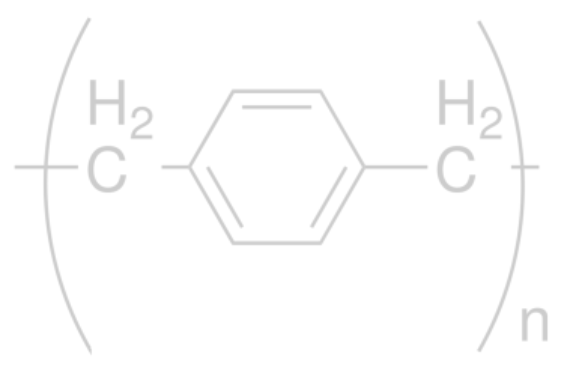

CX-PROTECT besteht aus Parylene, einem Polymer, das

CX-PROTECT bildet eine Barriere gegen Verunreinigungen, Chemikalien, Gase und Feuchtigkeit. Dank der außergewöhnlich niedrigen Gas- und Wasserdampfpermeationsraten, die zehnmal kleiner als Epoxidharz sind, bietet es einen Schutz mit einem Bruchteil der Masse von Tropensprays

CX-PROTECT ist eine hervorragende elektrische Isolierbeschichtung mit

CX-PROTECT ist die ideale Dünnschicht-Elektroisolierung für schmale oder platzbeschränkte Designs.

CX-PROTECT ist mit starren und flexiblen Leiterplatten und PCBA (Glasfasern, Polyimide) mit oder ohne Lötmasken kompatibel.

CX-PROTECT auf Leiterplatten widersteht dem Hochtemperatur-Löt-Reflow-Prozess oder Hunderten von thermischen Zyklen (Parylene-F-Qualität) ohne Delaminierung.

CX-PROTECT ist im gesamten sichtbaren Bereich hochtransparent und daher für optische Anwendungen äußerst nützlich. Der Brechungsindex liegt zwischen 1,5 und 1,6.

Für spezielle optische oder ästhetische Anwendungen wie Photonik oder Uhrmacherei hat COAT-X die Sorte ParyCLEAR entwickelt.

CX-PROTECT ist eine hervorragende Barriere gegen aggressive Chemikalien. Es widersteht den meisten in der Industrie verwendeten Lösungsmitteln, Säuren und Basen und ist in aggressiven Medien nicht löslich

CX-PROTECT besteht aus Parylene, einem hochleistungsfähigen teilkristallinen thermoplastischen Polymer mit hervorragenden mechanischen Eigenschaften.

COAT-X bietet Beschichtungsservice für CX-PROTECT-Schutzbeschichtungen für medizinische Geräte, elektronische Leiterplatten, Industriekomponenten, Schmuckstücke und Uhren.

Für die schnelle Bearbeitung von Bestellungen stehen Maschinen der neuesten Generation zur plasmaunterstützten chemischen Gasphasenabscheidung (PE-CVD) zur Verfügung.

Please fill in the fields below so we can contact you and define your needs