Despite advances in microfabrication of electronics and sensor technologies, active implants today still have relatively large volumes due to the limited scalability of traditional medical implant rigid housing-based encapsulation technologies.

Coat-X SA (Coat-X.com/) and the Wyss Center in Geneva (wysscenter.ch/) have joined forces to establish an encapsulation technology based on Coat-X’s high-performance barrier Parylene coatings that would allow replacement of the hard casings protecting active medical implants against corrosive body fluids. This innovative new thin film encapsulation technology enables miniaturization of implantable medical devices with active electronic components.

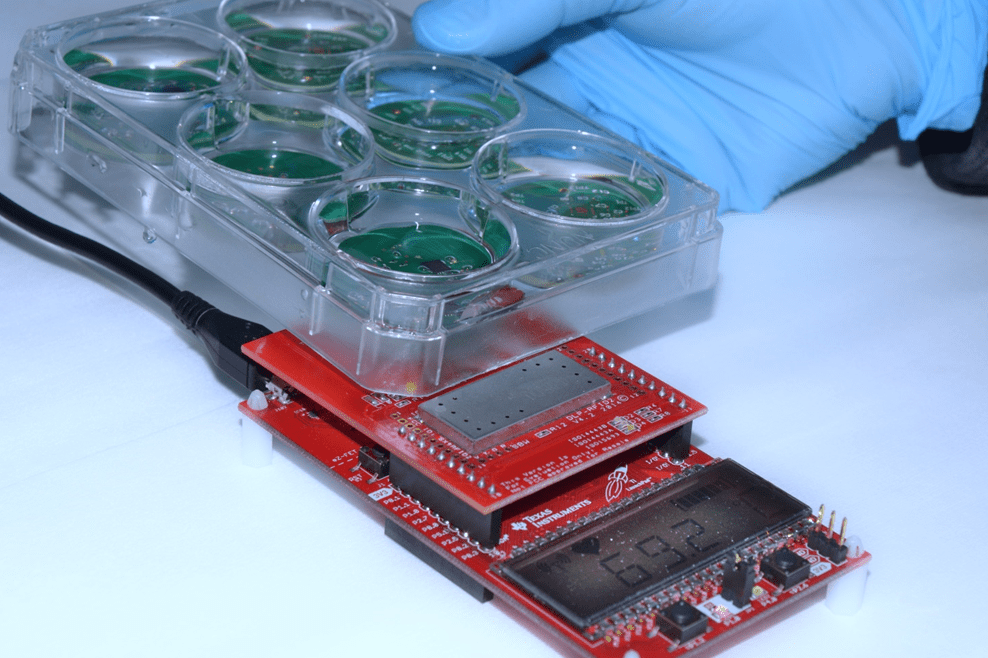

In the context of the collaboration, dedicated RF tags including sensing capabilities have been coated with a 10-micron thin multilayer film using Coat-X proprietary PE-CVD technology that combines organic Parylene and inorganic ceramics biocompatible layers. To verify the long-term performance of this coating technology in the human body, an accelerated aging platform was deployed at the Wyss Center to simulate the effects of real-time aging by subjecting the RF tags to elevated temperatures. As illustrated below, the tags have been immersed in 87°C Phosphate Buffered Solution (PBS) for 4 months to simulate more than 10 years implantation in the human body. Contactless interrogation of the RF tag was performed on a regular basis to verify proper function of the simulated implantable device.

We are proud to report that we have successfully reached the 10-year implantation milestone for the life expectancy of the coated active electronics, meaning that all tags remained functional for more than 4 months under the accelerated aging test briefly described above (acceleration factor of 32 according to the Arrhenius law).

The team is now working on establishing similar data for an equivalent 20 years of implantation!

Stay tuned for more results…

Coated PCBs immersed in saline solution are regularly interrogated wirelessly to check for device functionality with minimal manipulation. Setup for continuous interrogation inside the incubator is available at the Wyss Center to allow for monitoring of 40 samples simultaneously